The industry is an establishment that encounters manufacture of several products every day. So, there must be an efficient and durable system, which can ensure seamless functioning of the entire process and deliver optimum results. While detailing on this intricate system, bolts are nuts are noted as the building units, which must be enough strong and firm for proper facilitation of the production process. Though, there are a number of conventional materials being used for producing such units but, recently, engineers are in search of finer options that bring more strength and durability.

Resultantly, with the emergence of fibreglass bolts, it has gained wide popularity in the industrial sector because of its numerous beneficial aspects.

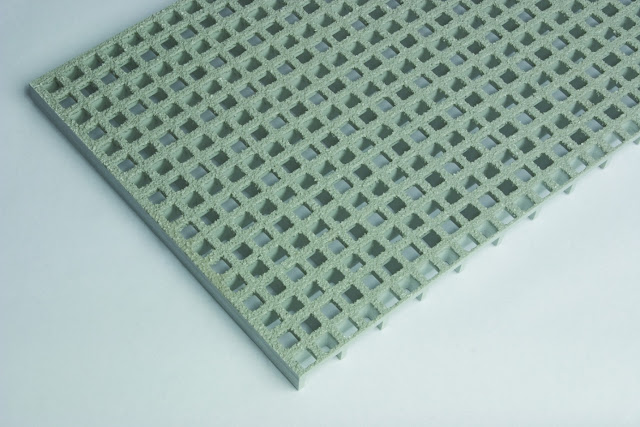

Composition

Composition of these products is being customized as per the requirement of customers. Often, fibreglass is manufactured by using carbon or steel brass, which is certainly used in the right proportion to make it as per the industrial standards. Moreover, user preference is another crucial factor, which is considered while manufacturing the fibreglass products. These units are also being galvanized for increasing the strength and making them less corrosive. Noticeably, a number of beneficial treatments are being used for instigating the exact properties to the fibreglass bolts.

Preparation process

A mixture of sand and chemicals are placed in the furnaces, where, it gets converted into a liquid form. This liquid is thereafter passed through a number of small holes. In this process, fibres are manufactured, which are further thinned to produce fibreglass yarns or chopped for making the fibreglass mats.

For producing a structure made of this material, the small glass fibres are being used in various layers for providing a concrete form to the product. Thereafter, polyepoxide is added for retaining the desired shape. When the epoxy or polyepoxide along surface of fibreglass gets hardened, the final product gains added strength. While the strongest form produced is the fibreglass yarns, the weakest is the chopped fibreglass mats.

Beneficial aspects of fibreglass bolts

A myriad of beneficial aspects can be noticed while using such products. They are robust, which can withstand extensive weight or pressure. They also come with the property of thermal resistivity, which makes them a perfectly usable one in environments encountering extensive heat. Since they are a mass produced good, they also come at affordable prices. Being the perfect product for the industry, these bolts help in increasing the productivity and so, promote cost-effectiveness. Moreover, they are easily installable and replaceable, and so, require lesser time and effort as well.

Final word

Because of versatility of the fibreglass bolts, it has become indispensable for the construction sector along with other significant heavy industries. Since, bolts are often considered as a core building block of a structure, the ones made of fibreglass are widely used because of their phenomenal features, thereby, promoting greater strength and durability.